- About

- Products

-

Brands

-

Yanmar

Yanmar is a renowned, more than a century old brand dedicated to innovation in engineering and technology, enhancing infrastructural productivity, providing compact diesel power solutions, technical expertise, etc.

-

Escorts

Escorts offers diverse range of construction and material handling equipments.

-

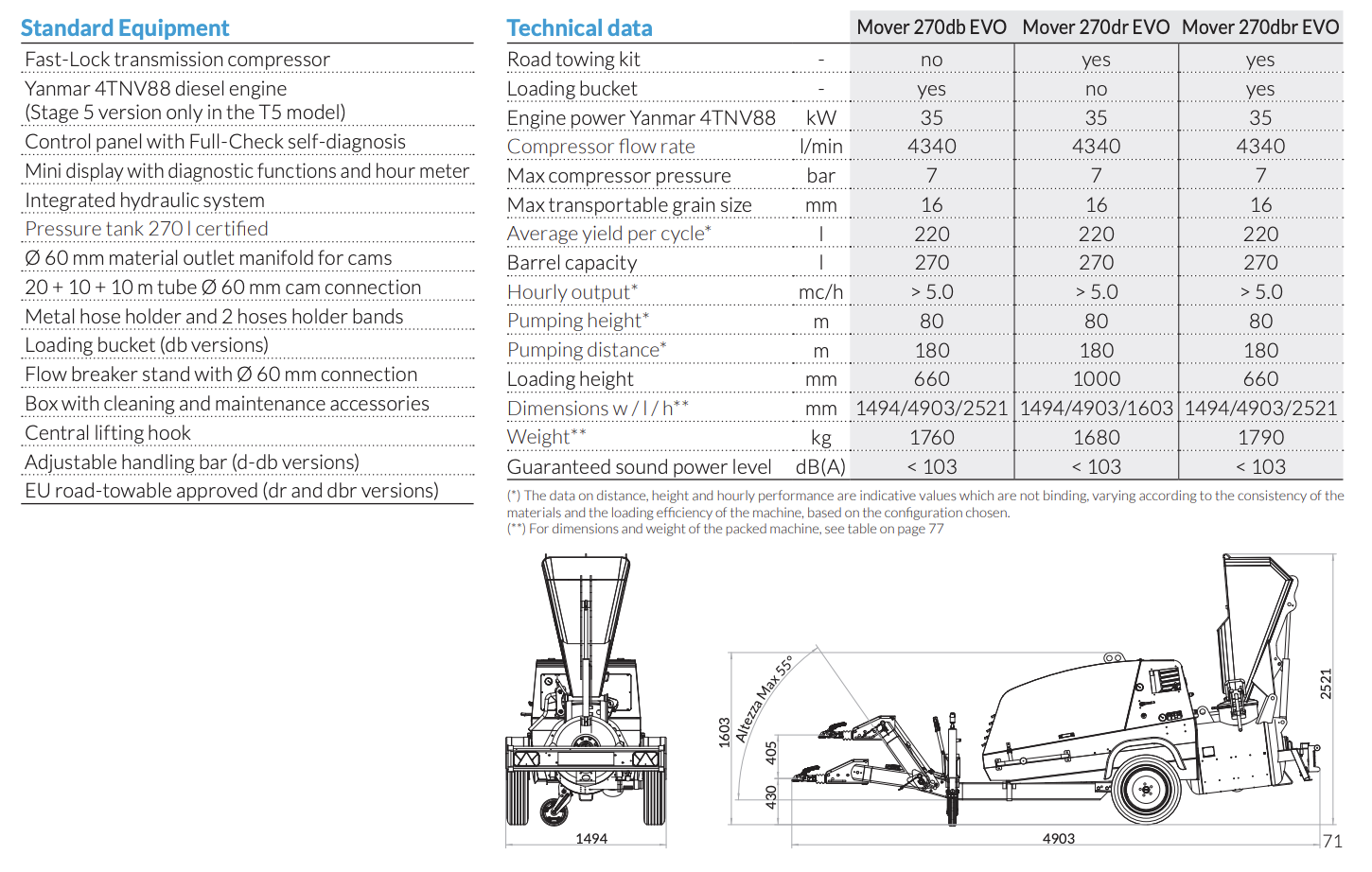

Imer

Over 50 years of experience in the sector and the continuous research of advanced technological solutions guarantee the quality of IMER brand machinery.

-

Swepac

FOR A SOLID GROUND Innovation and quality in all steps.

-

Kirloskar

Kirloskar Oil Engines Ltd. is renowned for manufacturing air-cooled and liquid-cooled diesel engines, suitable for both standby and prime power requirements.

-

Yale

Yale is one of the oldest and original manufacturers of lift trucks and warehouse equipments in the world. A wide range of quality products ensure effective execution of material handling tasks.

-

Bendi

Bendi's ‘Customer Comes First’ philosophy supports user-friendly approach and incorporates the best material handling techniques, providing unmatched manoeuvrability.

-

DP

DP Pumps is the global trade name of DP industries, Holland, that creates high quality pumps and systems for a variety of water applications. Smart hydraulic design ensures versatility and reliability.

-

Lubi

Lubi was established in 1965 and manufactures a wide variety of water pumps and motors, etc. Lubi holds the capacity to manufacture 700000 Units annually for domestic market and internationally, in more than 80 countries.

-

Oasis

Oasis Pumps Industry is the first and foremost indigenous manufacturer of de-watering pumps in the UAE.

-

ELGi

Elgi Equipments Limited is one of the leading air compressor manufacturer offering a wide range of technologically advanced air compressors used in various industries.

-

Xylem

With a diverse portfolio of brands including Lowara, Bell & Gossett, AC Fire Pump, and Flygt. Xylem is a renowned brand specializing in motor pumps & water solutions.

-

Landini

Landini tractors is a product of Argo Group, established in 2007. Argo tractors have been known across the world for its excellent quality and range, with effective agricultural applications.

-

Sonalika

Sonalika International tractors Ltd. is India's heavy duty tractor manufacturing company, producing best-selling tractors and well recognized in domestic and international market as the third largest player.

-

Yanmar

- Service

- Branches

- Career

- Contact